-

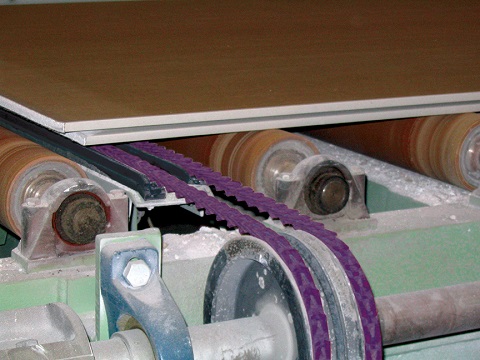

Gypsum Boards Production Line

The development of all gypsum boards begins with a mineral rock, which is gray to white in color and is called gypsum. The basic mineral is composed of calcium sulfate chemically combined with water of crystallization. The combined water makes up approximately 20% of weight of gypsum rock. This is the feature that gives gypsum its fire resistant quality and makes it so adaptable for construction purposes.

After gypsum rock is mined or quarried, it is crushed, dried, and ground to flour fineness, then calcined to drive off the greater part of the chemically combined water as steam. This calcined gypsum, commonly called plaster of paris, is then mixed with water and other ingredients and sandwiched between two sheets of specially manufactured paper to form various types of gypsum board or specially formulated and bagged for shipment as gypsum plaster or cement.

Gypsum boards are formed in a highly automated continuous process. After the gypsum board has set, the boards are cut to length, dried, prefinished if required, and packed for shipment. All processing is in strict accordance with specifications and complies with more than 256 procedures and work instructions to meet quality standards and customer's satisfaction.

ADVANTAGES

Life Safety Protection

Fire resistance is inherent in the gypsum construction selected. The systems provide permanent fire resistance not subject to loss of water pressure or other malfunctions and problems which may occur in sprinkler systems.

SPECIFICATIONS

It is ivory colour that is nice whether being painted or used as the end colour.

THICKNESS WIDTH LENGTH KG/M2

| S/N | thickness (cm) | width (cm) | length (cm) | volume (m 3) | weight (kg) |

|---|---|---|---|---|---|

| 1 | 9.0 | 12220 | 2440 | 268.3512 | 8.3 |

| 2 | 12.0 | 12220 | 2440 | 357.8016 | 12.0 |